I used to buy socks based purely on price and appearance. Cotton socks, synthetic socks, wool socks—they all seemed basically the same to me, just fabric tubes for your feet. Then I trained for my first marathon and discovered how brutally wrong I was. My cheap cotton running socks absorbed sweat like sponges, stayed wet for the entire run, and gave me blisters so bad I couldn’t walk normally for three days. One training partner wearing merino wool socks finished the same twenty-mile run with perfectly dry, blister-free feet.

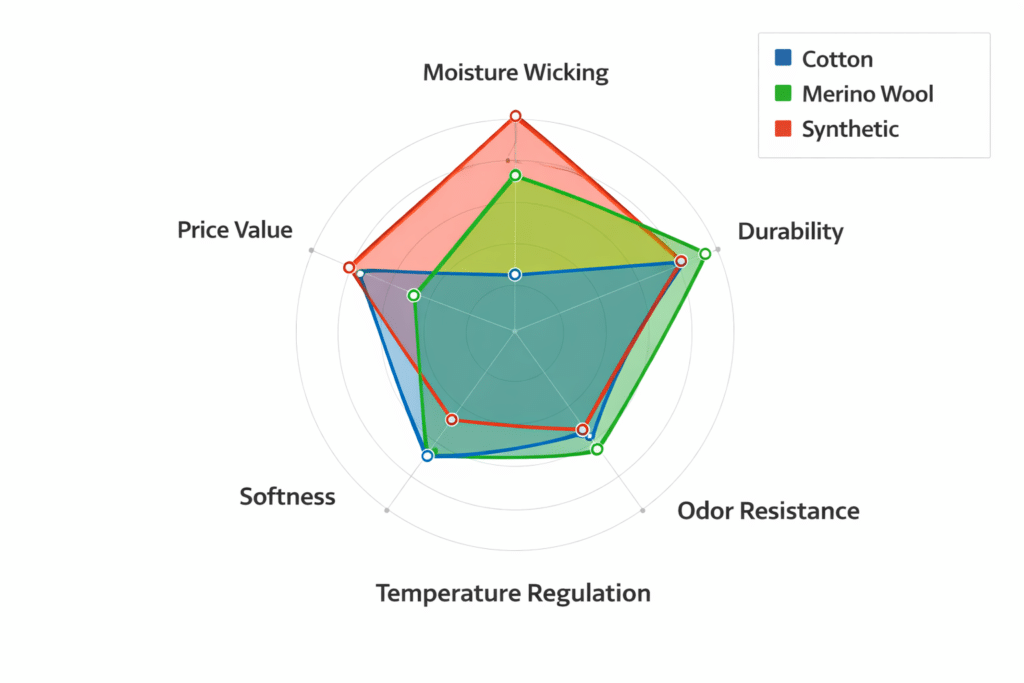

That painful experience sent me deep into sock material research. I learned that sock fabrics differ dramatically in moisture management, temperature regulation, durability, odor resistance, and feel. The material you choose affects comfort, performance, and how long socks last. Cotton excels in some situations but fails miserably in others. Merino wool costs more but delivers benefits that justify the price for certain activities. Synthetic blends offer engineered performance that natural fibers can’t match.

After testing dozens of sock materials across hundreds of activities—from hiking in rain to wearing dress socks in summer heat to practicing yoga in grip socks—I’ve learned exactly which materials work best for every situation. Whether you’re buying athletic socks, compression socks, dress socks, or casual everyday socks, understanding material properties ensures you choose fabrics that perform well for your specific needs rather than discovering their limitations through uncomfortable experience.

The Quick Answer: Best Sock Materials

The best sock material depends entirely on your intended use. Cotton works excellently for casual everyday wear in climate-controlled environments, but fails during athletic activities because it absorbs and retains moisture. Merino wool excels for temperature regulation, odor resistance, and moisture wicking, making it ideal for hiking, running, and multi-day wear, though it costs significantly more than other materials. Synthetic materials like polyester, nylon, and spandex provide superior moisture-wicking and durability for athletic activities at moderate prices. Bamboo offers softness and natural antimicrobial properties for casual wear. Most high-performance socks use blended materials combining natural and synthetic fibers to balance the strengths and weaknesses of each material type.

The fundamental principle of sock materials is that no single fiber does everything well. Each material excels in certain properties while struggling with others. Understanding these trade-offs helps you match sock materials to your specific activities rather than expecting one material to work perfectly for everything you do.

Understanding Sock Material Basics

Before comparing specific materials, let’s establish the key properties that determine how sock materials perform and which characteristics matter most for different uses.

Key Sock Material Properties

Moisture Management determines how fabric handles perspiration. Some materials absorb moisture and hold it (absorption), while others move moisture away from skin to the fabric surface where it evaporates (wicking). Your feet produce approximately half a cup of sweat daily, so moisture management dramatically affects comfort and foot health.

Temperature Regulation involves how materials insulate in cold conditions and breathe in warm conditions. Natural fibers like wool provide excellent insulation by trapping air between fibers. Synthetic materials often prioritize breathability over insulation. The best materials adapt to temperature changes rather than being optimized only for hot or cold.

Durability measures how well materials resist wear, pilling, holes, and degradation through washing. Some natural fibers, like cotton,n wear out relatively quickly, while quality synthetics and merino wool last significantly longer. Durability directly affects cost per wear, even when initial prices differ substantially.

Odor Resistance determines how quickly bacteria growth causes sock odor. Natural antimicrobial properties in materials like merino wool and bamboo resist odor development. Cotton and basic synthetics lack these properties and develop odor faster. This becomes critical for athletic socks or multi-day wear.

Softness and Comfort affect how socks feel againstthe skin. Natural fibers typically feel softer initially, but quality synthetics now match natural fiber softness. Some materials become softer with washing, while others roughen over time.

Elasticity and Stretch determine how well socks conform to foot shape and stay in place. Pure natural fibers have minimal stretch and require added elastic. Synthetic materials often provide inherent stretch. The right amount of elasticity prevents bunching and slipping.

For comprehensive guidance on how these properties affect specific sock types, check our detailed guide on the best moisture-wicking socks.

Natural vs Synthetic Materials

Natural materials (cotton, wool, bamboo) come from plant or animal sources. They tend to feel softer and more comfortable for casual wear. However, they often absorb moisture rather than wicking it, dry slowly, and wear out faster than synthetics. Natural fibers usually cost more to produce than basic synthetics.

Synthetic materials (polyester, nylon, acrylic, spandex) are manufactured through chemical processes. They excel at moisture wicking, dry quickly, resist wear, and cost less to produce. However, early synthetics felt plasticky and uncomfortable. Modern technical synthetics have largely overcome these issues.

Most performance socks use blended materials combining natural and synthetic fibers. Blends capture the comfort of natural fibers with the performance characteristics of synthetics, creating materials superior to either fiber alone.

How Fiber Construction Affects Performance

Beyond fiber type, how fibers are spun and woven dramatically affects sock performance. Fine merino wool fibers create softer, more comfortable socks than coarse wool. Tight weaves increase durability but may reduce breathability. Loose weaves breathe better but wear faster.

Modern sock manufacturing uses techniques like double-layer construction, mesh ventilation zones, and targeted cushioning placement. These construction methods work with material properties to optimize performance for specific uses.

Additionally, finishing treatments like antimicrobial coatings, water repellency, and reinforcement in high-wear areas enhance basic material properties. A cotton sock with quality finishing treatments performs differently from untreated cotton.

Cotton Socks: Pros, Cons, and Best Uses

Cotton is the most common sock material worldwide due to its availability, affordability, and comfortable feel. However, cotton’s popularity doesn’t mean it’s the best choice for every situation.

Advantages of Cotton Socks

Natural Softness makes cotton socks comfortable for everyday casual wear. The natural fiber feels gentle against the skin without the synthetic texture some people dislike. Quality cotton improves with washing, becoming softer through initial wear cycles.

Breathability allows air circulation that keeps feet cooler in warm conditions compared to some synthetic materials. This breathability works well for casual wear in climate-controlled environments where moisture management isn’t critical.

Affordability puts cotton socks at the lower end of the price spectrum. Basic cotton socks cost significantly less than merino wool or technical synthetics, making them economical for building large sock rotations.

Hypoallergenic Properties mean cotton rarely causes skin reactions. People with sensitive skin or allergies to synthetic materials often tolerate cotton better than alternatives.

Availability and Variety make cotton socks easy to find in any style, color, and pattern. The ubiquity of cotton means you can find options everywhere from discount stores to high-end retailers.

Disadvantages of Cotton Socks

Moisture Absorption and Retention represent cotton’s biggest weakness. Cotton absorbs up to 27 times its weight in water and holds that moisture against your skin. Wet cotton socks feel clammy, cause blisters through friction, and create environments where bacteria thrive and produce odor.

Slow Drying means cotton socks take hours to dry after becoming wet from sweat or washing. This slow drying makes cotton impractical for athletic activities, hiking, or any situation where you might need socks to dry quickly.

Poor Temperature Regulation When Wet causes cotton to lose insulating properties once damp. Wet cotton actually conducts heat away from your body, making it dangerous in cold conditions. The saying “cotton kills” in outdoor circles refers to hypothermia risk from wet cotton clothing.

Lower Durability compared to quality wool or synthetics means cotton socks develop holes and wear thin faster. The heel and toe areas particularly show wear after moderate use, requiring more frequent replacement.

Odor Development happens quickly in cotton socks because moisture retention creates ideal bacterial growth conditions. Cotton socks often smell noticeably after single-day wear, particularly during warm weather or physical activity.

Best Uses for Cotton Socks

Cotton works excellently for casual everyday wear in climate-controlled environments. Office workers in air-conditioned buildings wearing cotton dress socks or casual cotton crew socks experience cotton’s comfort without encountering its moisture management limitations.

Lounge socks and house socks benefit from cotton’s softness for relaxed home wear where performance doesn’t matter. The affordable pricing makes cotton reasonable for socks that see light use.

Cool weather casual wear, where you won’t sweatheavilyl,y allows cotton to shine. The breathability and softness make cotton pleasant for running errands, casual social activities, and general daily wear when conditions don’t promote heavy perspiration.

However, avoid cotton for athletic activities, hiking, long work shifts involving standing or walking, warm, humid conditions promoting sweat, or any situation where socks might get wet and need to dry quickly.

For detailed cotton sock alternatives for athletic use, see our comprehensive guide on the best running socks.

Merino Wool Socks: Complete Analysis

Merino wool represents the premium end of natural sock materials. Understanding what makes merino different from regular wool explains why it commands higher prices.

What Makes Merino Wool Special

Merino wool comes from Merino sheep, producing fibers significantly finer than regular wool (17-24 microns versus 30-40+ microns for standard wool). These fine fibers create a soft fabric that doesn’t itch like coarse wool.

The natural crimp in merino fibers traps air for exceptional insulation while allowing moisture vapor to pass through. This unique structure provides warmth without bulk and regulates temperature across wide ranges.

Merino fibers have a hydrophobic outer layer and a hydrophilic core. This allows them to wick moisture away from skin while the outer layer resists becoming saturated. Merino can absorb up to 30% of its weight in moisture while still feeling dry against skin.

Additionally, lanolin and the protein structure of merino wool naturally resist bacterial growth, preventing odor development even after multiple days of wear. This antimicrobial property makes merino ideal for travel and extended outdoor activities.

Advantages of Merino Wool Socks

Superior Temperature Regulation allows merino socks to keep feet warm in cold conditions and cool in warm conditions. The fiber structure adapts to environmental changes better than any synthetic material, making merino truly versatile across seasons.

Excellent Moisture Management wicks perspiration away from skin efficiently while the outer layer resists saturation. Unlike cotton, merino continues to insulate even when damp. This moisture performance rivals or exceeds quality synthetics while maintaining natural fiber comfort.

Natural Odor Resistance means merino socks can be worn multiple days without developing the smellthat cotton or basic synthetic socks produce after a single use. The antimicrobial properties inhibit bacterial growth that causes odor.

Exceptional Softness from fine merino fibers feels luxurious againstthe skin without any itchiness associated with traditional wool. Quality merino socks rival cashmere for softness while providing practical performance.

Durability: When Quality means well-made merino socks lastfor years with proper care. While not as abrasion-resistant as synthetics, quality merino resists pilling and maintains structure through extended use.

Natural Elasticity allows merino to stretch and recover shape without added elastic. This natural give creates a comfortable fit that conforms to foot shape.

Disadvantages of Merino Wool Socks

Higher Cost represents the primary barrier to merino adoption. Quality merino socks typically cost two to four times more than cotton or basic synthetic socks. However, the cost per wear often favors merino due to extended lifespan and multi-day wearability.

Longer Drying Time than synthetics means merino takes hours to air dry. While merino performs well when damp unlike cotton, the slow drying makes it less ideal than synthetics for situations requiring quick turnaround.

Care Requirements demand gentle washing and air drying to maintain quality. Machine drying merino can cause shrinkage and fiber damage. This extra care increases time investment compared to toss-and-go synthetics.

Potential Allergies affect some people who react to wool proteins. While merino causes fewer reactions than coarse wool, some individuals cannot wear any wool comfortably.

Variable Quality means not all merino socks perform equally. Cheap merino blends with low wool content don’t deliver the expected performance. Quality varies significantly between brands and price points.

Best Uses for Merino Wool Socks

Merino excels for hiking and backpacking, where temperature changes, moisture management, and multi-day wear without washing matter. The combination of performance characteristics makes merino ideal for outdoor activities.

Cold weather activities benefit from merino’s insulation and moisture management. Skiing, snowboarding, winter running, and cold weather work all see improved comfort with merino socks that keep feet warm without moisture buildup.

Travel socks leverage merino’s odor resistance for extended wear. Business travelers and backpackers value being able to wear merino socks multiple days, reducing luggage weight and washing frequency.

Athletic activities where odor resistance matters make merino appealing despite the higher cost. Serious runners, cyclists, and gym enthusiasts invest in merino for the performance and reduced odor compared to alternatives.

Everyday wear for people prioritizing comfort over cost finds merino delivering unmatched all-day comfort. The temperature regulation works beautifully for variable indoor-outdoor conditions.

For comprehensive merino wool sock recommendations, explore our detailed guide on the best wool socks.

Synthetic Sock Materials Explained

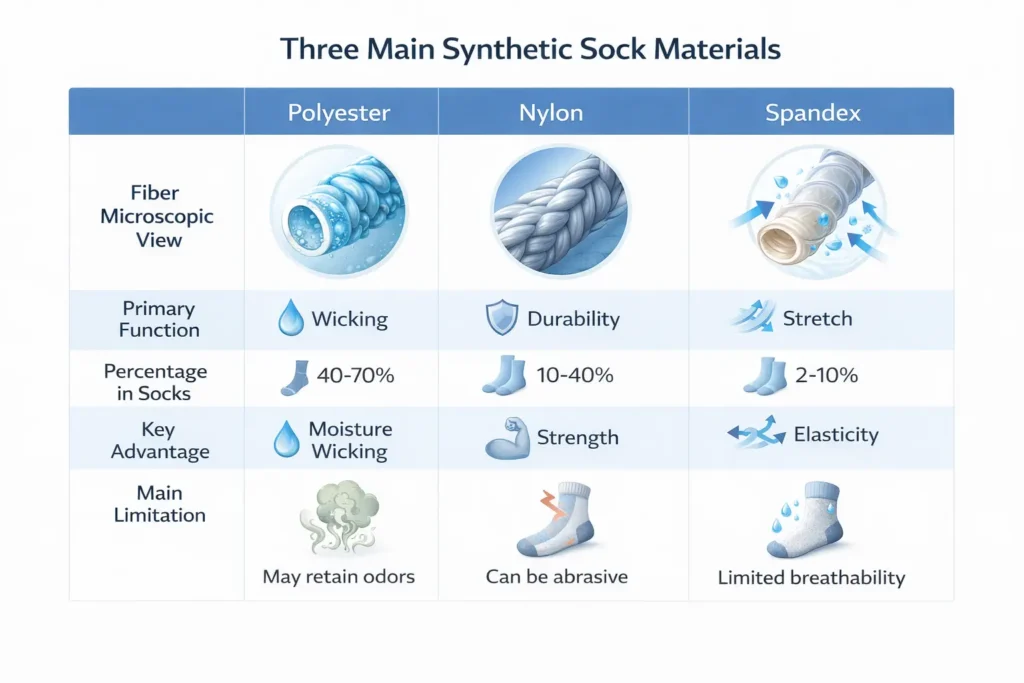

Synthetic materials dominate performance sock markets because they’re engineered for specific characteristics. Understanding different synthetics helps you choose the right technical materials.

Polyester in Socks

Polyester is the most common synthetic fiber in athletic and performance socks. It excels at moisture wicking by moving sweat to the fabric surface through capillary action where it evaporates quickly.

Advantages: Exceptional moisture wicking, fast drying (often dry within hours), excellent durability resistant to stretching and pilling, maintains shape through repeated washing, affordable compared to merino wool, easy care without special washing requirements.

Disadvantages: Can feel less soft than natural fibers, though modern polyester has improved significantly, may retain odors more than merino wool despite antimicrobial treatments, lacks the temperature adaptability of merino wool,and some people dislike the synthetic feel against skin.

Best Uses: Running socks, gym socks, hiking socks where fast drying matters, athletic activities with heavy perspiration, warm weather sports and activities.

The Nylon in Socks

Nylon provides exceptional strength and abrasion resistance, making it ideal for reinforcement in high-wear areas like heels and toes. Nylon often blends with other materials rather than being used alone.

Advantages: Superior durability and abrasion resistance, adds strength to natural fiber blends, smooth texture feels comfortable, elastic properties help socks stay in place, quick drying like polyester, resists pilling better than many materials.

Disadvantages: Limited moisture wicking when used alone, can feel slippery in some constructions, may retain odors without treatments, less breathable than some alternatives.

Best Uses: Reinforcement in heel and toe areas of athletic socks, blending with merino or other materials for durability, hiking socks where abrasion resistance matters, dress socks requiring smooth finish and durability.

Acrylic in Socks

Acrylic mimics wool’s softness and warmth at lower cost. It’s common in casual and dress socks where comfort matters more than moisture-wicking performance.

Advantages: Wool-like softness and warmth, affordable pricing, hypoallergenic alternative to wool, easy care and machine washable, resists moths and mildew unlike wool, maintains shape well.

Disadvantages: Poor moisture wicking compared to polyester, can pill with wear and washing, retains odors more readily than wool or treated polyester, less durable than nylon or quality polyester, can feel hot in warm conditions.

Best Uses: Casual everyday socks in cool weather, dress socks where appearance and comfort matter more than performance, budget-friendly warm socks, and people with wool allergies seeking a wool-like feel.

Spandex and Elastane in Socks

Spandex (also called elastane or Lycra) isn’t used alone but added to other materials to provide stretch and recovery. Even small percentages dramatically improve sock fit and performance.

Advantages: Exceptional stretch and recovery maintain sock shape, help socks stay up without slipping, enables compression sock functionality, improve overall fit and comfort, small percentages needed (2-5% typical), enhanced durability by reducing stress on other fibers.

Disadvantages: Can degrade with heat exposure requiring air drying, breaks down over time l, losing elasticity, some people react to elastic materials, and increases cost slightly over non-stretch alternatives.

Best Uses: Athletic socks requiring snug fit, compression socks where graduated compression is essential, no-show and grip socks needing to stay positioned, any sock where fit security matters.

For detailed guidance on compression sock materials and construction, see our comprehensive article on the best compression socks.

Modern Technical Synthetics

Brand-name technical fabrics like CoolMax, Dri-FIT, and others are engineered polyester variants optimized for specific performance characteristics.

These materials use modified fiber shapes, surface treatments, and construction techniques to enhance moisture wicking, breathability, and comfort beyond standard polyester. While marketing can exaggerate differences, quality technical fabrics do perform measurably better than basic synthetics.

The premium for brand-name technical fabrics varies. Sometimes you’re paying primarily for marketing, other times the performance improvement justifies the cost. Reading independent reviews and testing yourself determines whether specific technical fabrics deliver value for your needs.

Bamboo and Specialty Natural Fibers

Beyond cotton and wool, specialty natural fibers offer unique properties that appeal to specific preferences and needs.

Bamboo Viscose Socks

Bamboo fabric for socks typically comes from bamboo viscose, a processed material rather than natural bamboo fiber. The processing involves dissolving bamboo cellulose and reforming it into fibers.

Advantages: Exceptionally soft and silky texture rivals or exceeds cotton softness, natural antimicrobial properties resist odor development, good moisture absorption for casual wear, sustainable and renewable resource, biodegradable unlike synthetics, breathable for warm weather comfort.

Disadvantages: Processing involves chemicals, despite the natural source material, resulting in lower durability compared to wool or synthetics. This requires more frequent replacement. Additionally, it has limited moisture-wicking compared to merino or synthetics, shrinks more readily than alternatives, and requires careful washing. Furthermore, it has a higher cost than cotton without matching merino performance. The environmental impact of viscose processing varies by manufacturer.

Best Uses: Casual everyday socks where softness is a priority, warm weather socks for non-athletic wear, individuals seeking sustainable options, those with sensitive skin, dress socks where a smooth texture and antimicrobial properties are important, and diabetic socks where softness and non-binding properties are beneficial.

For bamboo sock applications in specialized contexts, see our guide on the best diabetic socks for women.

Silk Socks

Silk rarely appears in mainstream socks but offers unique properties for specialized uses.

Advantages: Luxurious smooth texture, natural temperature regulation, excellent moisture wicking for a natural fiber, strong despite lightweight feel, hypoallergenic properties.

Disadvantages: Very expensive, delicate, requiring hand washing, poor durability for footwear, limited availability, and impractical for athletic use.

Best Uses: Liner socks for hiking under main socks, luxury dress socks for special occasions, thin socks for tight-fitting dress shoes, and for people with extreme sensitivity to other materials.

Hemp Socks

Hemp is an emerging sock material offering sustainability benefits and unique properties.

Advantages: Extremely durable and long-lasting, naturally antimicrobial and odor resistant, a sustainable crop requiring minimal water and pesticides, becomes softer with washing, and has good breathability.

Disadvantages: Can feel rough initially before breaking in, limited availability compared to mainstream materials, higher cost than cotton, less stretch than some alternatives, and limited moisture-wicking performance.

Best Uses: Casual socks where durability and sustainability matter, people seeking eco-friendly options, warm weather casual wear, and those willing to invest in longevity.

Blended Materials and Why They Work

Most performance socks use material blends combining multiple fibers. Understanding blend ratios helps you predict sock performance.

Why Blend Materials

Single materials excel in some properties while struggling with others. Blending captures strengths while minimizing weaknesses. For example, merino wool provides comfort and odor resistance but lacks durability. Adding nylon increases strength while maintaining wool’s benefits.

Blends also control cost. Pure merino socks are expensive. Blending 70% merino with 28% nylon and 2% spandex reduces cost while delivering most of merino’s performance plus improved durability and fit.

Additionally, blends enable specific performance characteristics impossible with single materials. Compression socks require spandex for graduated compression but use other fibers for comfort and moisture management.

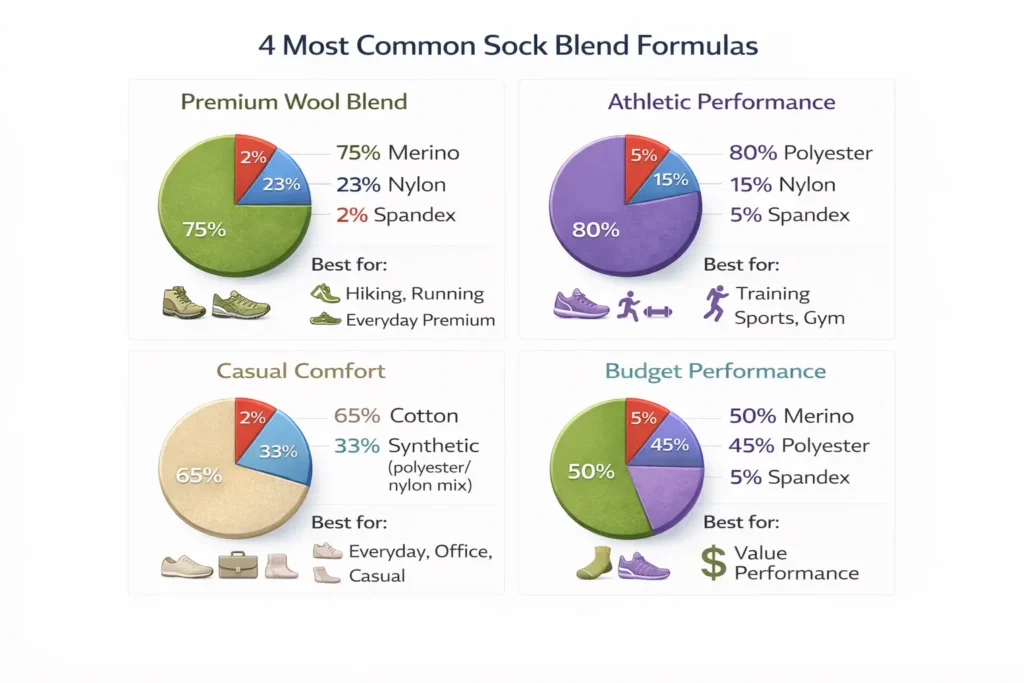

Common Blend Ratios and Their Purposes

70-80% Merino Wool, 20-28% Nylon, 2% Spandex: The gold standard for performance wool socks. Delivers merino’s comfort and moisture management with nylon’s durability and spandex’s fit. Common in hiking, running, and everyday premium socks.

70-85% Polyester, 10-25% Nylon, 3-5% Spandex: Typical athletic sock blend. Polyester wicks moisture, nylon adds durability in the heel/toe, and spandex provides compression and fit. Found in most performance running and training socks.

60-70% Cotton, 30-38% Polyester/Nylon, 2% Spandex: Casual sock blend balancing cotton comfort with synthetic performance. The synthetic content improves moisture management and durability over pure cotton while maintaining a soft feel.

50% Bamboo, 45% Cotton, 5% Spandex: Casual comfort blend combining bamboo softness with cotton familiarity and spandex fit. Common in everyday casual and dress socks, prioritizing feel over athletic performance.

40-50% Merino, 40-50% Polyester, 5-10% Spandex: Balanced performance blend for athletic activities. Combines merino’s comfort and odor resistance with polyester’s moisture-wicking and fast drying. Popular in running and cycling socks.

Reading Sock Material Labels

Sock labels list materials in descending order by percentage. The first material is the primary component; subsequent materials are secondary ingredients.

Pay attention to the percentage of key materials. A sock listing merino wool first but only containing 30% merino wool won’t perform like a 70% merino sock. Marketing may emphasize merino while the sock is primarily synthetic.

For specialized socks, specific percentages matter. Compression socks need adequate spandex for compression functionality. Grip socks work best with specific material ratios that balance grip coating adhesion with comfort and moisture management.

Some brands hide exact percentages, listing only materials without ratios. This makes evaluating quality difficult. Premium brands typically specify exact percentages because they’re proud of their blend formulations.

For detailed analysis of how material blends affect specific sock types, see our guides on best grip socks and best grip socks for Pilates.

Budget Blends vs Premium

Premium blends use quality versions of each fiber. Premium merino uses fine micron counts, quality nylon, and durable spandex. Budget blends may claim similar ratios but use lower-quality versions of each material.

The difference appears in performance and longevity. Premium blends maintain shape, resist pilling, and deliver consistent performance through hundreds of washes. Budget blends may wear quickly, lose elasticity, develop holes, and underperform marketing claims.

Price often indicates quality in blended socks. Socks claiming 70% merino at cotton prices likely use low-grade merino or inaccurate labeling. Quality materials cost more to source and manufacture.

Choosing Materials by Activity

Matching sock materials to specific activities ensures optimal performance and comfort.

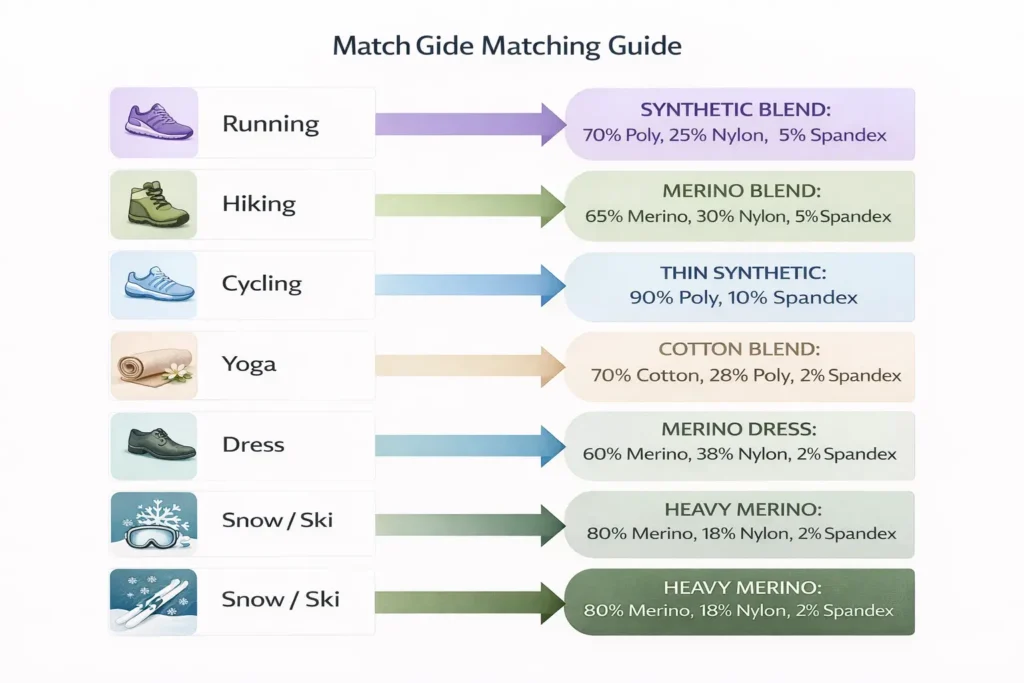

Running and High-Impact Sports

Best Materials: Synthetic blends (polyester/nylon) or merino-synthetic blends

Why: Moisture wicking prevents blisters, fast drying handles heavy sweat, and durability withstands high-friction movement

Recommended Blend: 70-80% polyester, 15-25% nylon, 3-5% spandex

Alternative: 50% merino, 45% polyester, 5% spandex for odor resistance

Running generates significant heat and perspiration. Synthetics wick this moisture efficiently, preventing the soggy, blister-causing conditions cotton creates. The fast drying means socks stay comfortable throughout long runs.

Reinforced heel and toe areas using nylon improve longevity in high-wear zones. Arch compression from spandex prevents bunching that causes hot spots.

Avoid pure cotton for any serious running. The moisture retention guarantees blisters on runs exceeding 30 minutes.

For comprehensive running sock material guidance, see our detailed article on the best running socks.

Hiking and Backpacking

Best Materials: Merino wool blends

Why: Temperature regulation across conditions, multi-day wearability without odor, moisture management that works even when damp

Recommended Blend: 70% merino, 28% nylon, 2% spandex

Budget Alternative: 50% merino, 45% synthetic, 5% spandex

Hiking involves extended wear, variable temperatures, and potential for getting wet. Merino’s temperature adaptation keeps feet comfortable whether climbing in the sun or descending into cool valleys.

The odor resistance allows wearing socks for multiple days on backpacking trips, reducing pack weight. Merino continues insulating when damp from creek crossings or rain, unlike cotton that becomes dangerous when wet.

Nylon reinforcement in the heel and toe prevents holes from boot friction during long trail miles.

For hiking-specific sock recommendations, explore our guide on the best hiking socks.

Cycling

Best Materials: Thin synthetic blends or merino-synthetic blends

Why: Smooth fit in cycling shoes, moisture-wicking for enclosed feet, quick drying for multi-hour rides

Recommended Blend: 75% polyester, 20% nylon, 5% spandex

Alternative: 60% merino, 35% polyester, 5% spandex

Cycling shoes fit tightly, making smooth sock construction essential. Thin materials prevent pressure points while providing moisture management.

The enclosed nature of cycling shoes traps heat and moisture. Wicking materials prevent the swampy conditions that cause numbness and discomfort.

Some cyclists prefer merino blends for multi-hour rides where odor resistance and temperature regulation matter more than absolute thinness.

For cycling-specific guidance, see our article on best cycling socks.

Yoga, Pilates, and Barre

Best Materials: Cotton blends or bamboo blends for grip sock compatibility

Why: Grip coatings adhere well to natural fiber blends, provide comfort for barefoot-style practice, and are breathable for studio environments

Recommended Blend: 80% cotton, 18% polyester, 2% spandex

Alternative: 70% bamboo, 28% polyester, 2% spandex

Studio workouts require grip socks to prevent slipping on smooth floors or carpets. Silicone and rubber grip patterns bond more effectively to natural fiber bases than pure synthetics.

The controlled studio environment means extreme moisture wicking is less critical than for outdoor running. Comfort and breathability take priority while maintaining enough synthetic content for durability and shape retention.

Bamboo blends offer antimicrobial properties that reduce odor in socks worn frequently for classes, while the soft texture feels comfortable during poses and movements.

For studio sock material specifics, see our comprehensive guides on best grip socks for Pilates, best grip socks for yoga, and barre socks.

Office and Dress Wear

Best Materials: Merino wool blends or fine synthetic dress blends

Why: Temperature regulation in climate-controlled offices, odor resistance for all-day wear, smooth texture under dress shoes

Recommended Blend: 75% merino, 23% nylon, 2% spandex

Budget Alternative: 70% acrylic, 28% nylon, 2% spandex

Office workers spend eight-plus hours in the same socks, often transitioning between air-conditioned spaces and outdoor heat. Merino’s temperature adaptation keeps feet comfortable through these changes.

The odor resistance prevents the embarrassment of smelly feet when removing shoes. All-day comfort matters more than athletic performance characteristics.

Thin, smooth construction fits properly in dress shoes without bunching. Over-the-calf styles stay up throughout the day without garters.

Budget alternatives using acrylic provide a wool-like feel at a lower cost, though they lack merino’s moisture management and odor resistance.

Casual Everyday Wear

Best Materials: Cotton blends or bamboo blends

Why: Softness for all-day comfort, breathability in normal conditions, affordable for building large sock rotations

Recommended Blend: 70% cotton, 28% polyester, 2% spandex

Alternative: 65% bamboo, 33% polyester, 2% spandex

Everyday casual wear doesn’t demand extreme performance characteristics. Comfort, affordability, and availability take priority over technical features.

Cotton blends provide the familiar soft feel people expect from casual socks, while synthetic additions improve durability and moisture management compared to pure cotton.

The key is having enough socks to rotate frequently, so individual pair longevity matters less than for expensive performance socks.

For casual sock recommendations across styles, explore our guides on best ankle socks and best crew socks.

Cold Weather Activities

Best Materials: Merino wool blends with higher wool percentages

Why: Superior insulation, moisture management prevents sweat from cooling feet, warmth retention even when damp

Recommended Blend: 80% merino, 18% nylon, 2% spandex

Heavyweight Option: 85% merino, 15% nylon for extreme cold

Winter activities from skiing to winter running to snow shoveling, require warmth without moisture buildup. Merino insulates while wicking perspiration away from skin.

The ability to maintain warmth when damp protects against dangerous cooling from sweat accumulation. Cotton becomes a hypothermia risk in cold conditions because wet cotton conducts heat away from the body.

Heavier merino percentages increase insulation for extreme cold, while maintaining enough nylon for durability in boot friction areas.

Compression and Medical Socks

Best Materials: Synthetic-dominated blends with significant spandex

Why: Graduated compression requires elastic fibers, moisture wicking for extended wear, durability for therapeutic use

Recommended Blend: 70% nylon, 25% spandex, 5% other

Alternative: 60% polyester, 35% spandex, 5% merino

Compression socks require substantial spandex content (20-35%) to provide graduated compression pressure. Natural fibers alone can’t deliver the compression levels needed for medical benefits.

Nylon or polyester base provides moisture-wicking for all-day wear by nurses, travelers, or people with medical conditions requiring compression.

Some premium compression socks add small percentages of merino for comfort and odor resistance, but the synthetic base remains essential for compression functionality.

For comprehensive compression sock material analysis, see our detailed articles on the best compression socks and compression socks for nurses.

Material Care and Longevity

Proper care extends sock life and maintains performance characteristics. Different materials require different care approaches.

Washing Different Sock Materials

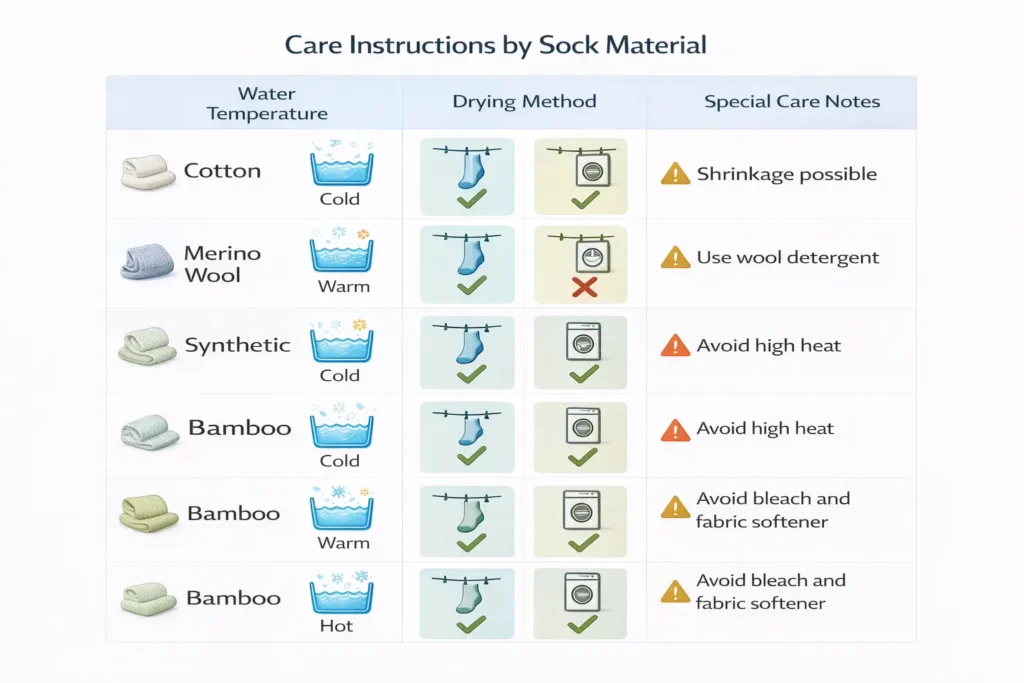

Cotton Socks: Wash in warm or cold water, tumble dry on low heat acceptable. Cotton tolerates machine washing and drying well, though high heat can cause shrinkage. Fabric softener is optional but can reduce moisture absorption slightly.

Merino Wool Socks: Wash in cold water on gentle cycle, air dry flat or hang to dry. Merino requires gentler care than cotton. Hot water and machine drying can cause shrinkage and fiber damage. Wool-specific detergents maintain fiber quality better than standard detergents. Never use fabric softener on wool.

Synthetic Socks: Wash in cold or warm water, air dry or low heat tumble dry. Most synthetics tolerate machine washing well. However, high heat can damage spandex fibers over time, reducing elasticity. Avoid fabric softener which can coat technical fabrics and reduce moisture-wicking performance.

Bamboo Socks: Wash in cold water on gentle cycle, air dry to prevent shrinkage. Bamboo viscose shrinks more readily than cotton, requiring careful washing. Gentle detergents preserve fiber softness better than harsh alternatives.

Compression Socks: Hand wash or gentle machine wash in cold water, air dry only. The high spandex content in compression socks degrades with heat exposure. Hand washing in a mesh bag protects the elastic fibers. Never machine-dry compression socks.

For detailed sock care instructions applicable to all materials, see our comprehensive guide on how to wash grip socks.

Drying Methods and Material Effects

Air Drying: Best for all sock materials, particularly merino wool, bamboo, and compression socks. Lay flat or hang to dry away from direct heat and sunlight. Air drying preserves fiber structure, maintains elasticity, prevents shrinkage, and extends overall sock life.

Low Heat Tumble Drying: Acceptable for cotton and most synthetic blends. Use the lowest heat setting and remove socks promptly when dry. Extended high heat damages spandex and can shrink natural fibers.

High Heat Drying: Avoid for all sock types. High heat shrinks natural fibers, degrades spandex elasticity, can damage technical fabric treatments, and accelerates overall wear.

Drying Time by Material: Cotton takes longest (4-6 hours air drying), merino wool takes a moderate time (3-5 hours), synthetics dry fastest (1-3 hours), and bamboo takes a moderate-long time (3-6 hours).

Storage and Maintenance

Store socks flat or loosely paired rather than tightly rolled. Tight rolling stresses elastic fibers over time, particularly in compression socks and athletic socks with significant spandex content.

Keep sock drawer organized by material type and use. Separating running socks from dress socks from casual socks prevents grabbing the wrong material for activities.

Rotate socks rather than wearing favorites repeatedly. This distributes wear across all pairs, extending the lifespan of your entire sock collection.

Inspect socks regularly for signs they need replacement. Thinning fabric, holes developing, elastic becoming loose, or grip patterns wearing away indicate it’s time for new socks.

Material Longevity Comparison

Most Durable: Quality merino wool blends (12-24 months heavy use), nylon-heavy synthetic blends (12-18 months), premium technical synthetics (12-18 months)

Moderate Durability: Cotton-synthetic blends (6-12 months), acrylic blends (6-10 months), bamboo blends (6-12 months)

Less Durable: Pure cotton (3-6 months heavy use), low-quality synthetic blends (3-6 months), bargain merino blends (4-8 months)

These ranges assume proper care and regular use. Athletic socks seeing daily training wear out faster than casual socks worn weekly. Poor care (hot water washing, machine drying merino) dramatically reduces longevity across all materials.

Cost Per Wear Analysis

While premium materials cost more initially, cost per wear often favors quality investments.

Premium Merino Socks: $20-30 per pair, lasting 18 months = $0.04-0.05 per wear (assuming 3x weekly wear)

Quality Synthetic Socks: $12-18 per pair, lasting 12 months = $0.06-0.12 per wear

Cotton-Synthetic Blend: $8-12 per pair, lasting 8 months = $0.08-0.12 per wear

Budget Cotton Socks: $4-6 per pair, lasting 4 months = $0.08-0.12 per wear

The premium materials deliver better performance throughout their lifespan while often costing the same or less per wear than budget alternatives requiring frequent replacement.

Frequently Asked Questions About Sock Materials

Material Comparison Questions

What’s the best sock material overall? No single material is best for everything. Merino wool offers the most versatility across activities and conditions, but costs more. Synthetic blends excel for athletic performance at moderate prices. Cotton works well for casual wear in controlled environments. Choose based on your primary sock use.

Is merino wool worth the extra cost? For hiking, running, travel, and situations where odor resistance and temperature regulation matter, yes. For casual everyday wear where you have many pairs and wash after single use, premium merino may be overkill. Consider your specific needs and budget.

What’s the difference between cheap and expensive socks of the same material? Quality varies significantly within material categories. Expensive merino uses finer fibers, better construction, and higher percentages. Cheap merino blends may use coarse wool or low wool percentages. Quality synthetics use engineered fibers while cheap synthetics use basic polyester. Construction quality also differs dramatically.

Can you mix different material socks in the same load of laundry? Yes, but wash on settings appropriate for the most delicate material in the load. Washing merino socks with cotton means using cold water and gentle cycle appropriate for merino, which is fine for cotton too. However, this extends wash time compared to washing cotton separately on normal settings.

Do sock materials affect foot odor? Absolutely. Merino wool and bamboo naturally resist odor-causing bacteria. Synthetics often include antimicrobial treatments but may still develop odor faster than wool. Cotton has no odor resistance and smells quickly when damp. Material choice significantly impacts how often socks smell after wearing.

Performance Questions

Which material wicks moisture best? Quality synthetic blends (polyester-based) and merino wool both wick moisture excellently but through different mechanisms. Synthetics move moisture to the surface for evaporation. Merino absorbs moisture into fibers while feeling dry on surface. For pure wicking speed, synthetics edge out wool.

What material keeps feet warmest in winter? Merino wool provides superior warmth through air-trapping insulation while managing moisture that would otherwise cool feet. Wool maintains warmth even when damp. Cotton loses almost all insulation when wet. Synthetics insulate moderately but don’t match wool’s performance in cold conditions.

Which material dries fastest? Synthetic materials dry fastest, often within 1-3 hours when air drying. Merino wool takes 3-5 hours. Cotton takes 4-6+ hours. Bamboo falls between cotton and wool. For activities requiring quick turnaround or travel with limited drying time, synthetics win clearly.

Do cotton socks cause more blisters? Yes, because cotton absorbs and retains moisture that increases friction. Wet cotton against skin during repetitive movement (running, hiking) causes blisters much more readily than moisture-wicking materials. For blister prevention, avoid cotton in athletic socks.

Are synthetic socks bad for your feet? Quality synthetics are not harmful. Early synthetics felt uncomfortable and trapped heat, but modern technical fabrics breathe well and feel comfortable. Some people prefer natural fibers, but that’s personal preference rather than synthetics being unhealthy. Poor quality synthetics can feel plasticky and hot.

Material Selection Questions

What material is best for sweaty feet? Merino wool and quality synthetic blends both manage moisture well. Merino adds natural odor resistance that helps with the smell of sweaty feet smell. Bamboo offers moderate moisture management with antimicrobial properties. Avoid cotton, which absorbs sweat and stays wet.

What sock material is best for diabetics? Soft, non-irritating materials like bamboo, quality cotton blends, or fine merino wool work well. Seamless construction matters more than specific material for diabetics. Avoid rough synthetics and materials with aggressive elastic that can restrict circulation. See our guide on diabetic socks for women for detailed recommendations.

Which material is best for sensitive skin? Merino wool (fine micron count), bamboo, and quality cotton cause the fewest skin reactions. Some people react to wool proteins, making bamboo or cotton better choices. Avoid cheap rough synthetics. Seamless construction in any material reduces irritation.

Are bamboo socks better than cotton? Bamboo offers advantages: softer texture, better moisture absorption, natural antimicrobial properties, and more sustainable production. However, bamboo costs more and isn’t significantly better than cotton for casual wear. For athletic use, neither bamboo nor cotton performs well; choose synthetics or wool instead.

What’s the most sustainable sock material? Merino wool from ethical farms and organic cotton rate well for sustainability. Bamboo grows quickly with minimal resources,s but processing into viscose uses chemicals. Recycled synthetic materials (recycled polyester) offer sustainability in synthetic category. Hemp is extremely sustainable but less available. True sustainability depends on the entire supply chain, not just fiber source.

Practical Use Questions

Can I wear wool socks in summer? Yes, quality merino wool regulates temperature and keeps feet comfortable in warm weather through moisture wicking and breathability. However, choose lightweight merino socks rather than heavyweight winter versions. Some people prefer synthetics or bamboo in extreme heat.

How do I know if socks are good quality without trying them? Check material percentages (higher quality fiber percentages), read customer reviews mentioning durability, examine construction quality in person (smooth seams, even knitting), consider brand reputation, and recognize that very cheap prices usually indicate low quality materials.

Should running socks be cotton or synthetic? Synthetic or merino-synthetic blends. Never pure cotton for running. Cotton absorbs sweat, stays wet, and causes blisters. Quality running socks use moisture-wicking materials that keep feet dry. This is one of the clearest material recommendations in all of sock selection.

Do expensive materials prevent blisters better? Material quality contributes to blister prevention through moisture management and seam construction, but proper fit matters more than material alone. Well-fitting synthetic socks prevent blisters better than poorly fitting premium merino. Combine good materials with proper sizing and seamless construction for best results.

Can sock material help with cold feet? Merino wool helps significantly through insulation and moisture management. Cold feet are often caused by dampness from perspiration. Wool keeps feet dry while insulating, addressing both causes of cold feet. Cotton makes cold feet worse by retaining moisture.

Care and Maintenance Questions

How often should you replace socks based on the material? Quality merino wool socks last 12-24 months with regular use and proper care. Synthetic athletic socks last 12-18 months. Cotton blends last 6-12 months. Budget socks need replacement every 3-6 months. Replace when the material thins, holes develop, or elastic fails.

Does washing ruin sock materials? Improper washing damages materials. Hot water and machine drying harm merino wool. High heat damages spandex in all socks. Proper care (cold water, gentle cycle, air drying for delicate materials) maintains sock performance for their full lifespan.

Can you restore worn sock materials? Not really. Once materials thin, holes develop, or elastic degrades, they can’t be restored to original performance. Some people darn holes to extend casual sock life, but performance socks with compromised materials should be replaced.

Why do some socks pill and others don’t? Material quality and fiber length affect pilling. Short fiber materials pill more readily. Quality merino uses long fibers that resist pilling. Cheap acrylic pills extensively. Synthetic blends vary based on quality. Higher-quality materials pill less.

How do you remove odor from socks? Wash properly with adequate detergent. For stubborn odors, soak in vinegar solution (1 cup white vinegar per gallon water) for 30 minutes before washing. Merino wool resists odor naturally. Synthetics may need antimicrobial treatment. Cotton retains odors more readily. If odor persists after proper washing, bacteria have penetrated the fiber,s and the socks need replacement.

Internal Links and Related Resources

Understanding sock materials connects to broader topics about choosing and caring for specialized socks. Exploring these related areas helps you make informed decisions about your complete sock wardrobe.

Learning about specific sock types and their material requirements helps you understand why certain fabrics work better for particular activities. Our comprehensive guide on best grip socks explains why natural fiber bases bond better with silicone grip patterns.

Comparing different athletic sock materials reveals performance differences. Reviewing the best running socks versus the best cycling socks shows how the same activity category benefits from slightly different material formulations.

Understanding how materials affect compression functionality is crucial for medical and athletic compression socks. See our detailed guides on the best compression socks and compression socks for swollen feet for material-specific compression analysis.

Exploring specialty sock materials for studio workouts shows how grip sock construction requires material considerations beyond standard athletic socks. Check our guides on best grip socks for Pilates, best grip socks for yoga, and barre socks for activity-specific material guidance.

Learning about materials for medical applications reveals how fiber selection affects therapeutic benefits. Our articles on diabetic socks for women and compression socks for plantar fasciitis explain material requirements for medical conditions.

Understanding how materials affect sock longevity and care connects to maintenance best practices. Our comprehensive guide on how to wash grip socks provides care instructions that apply to all material types.

For seasonal material selection, explore our guides on the best wool socks for cold weather and best moisture-wicking socks for warm-weather activities.

Final Thoughts on Choosing the Right Sock Materials

Sock materials determine how comfortable your feet feel, how well socks perform during activities, and how long they last before requiring replacement. The explosion of material options beyond basic cotton means you can now match sock fabrics precisely to your specific needs rather than accepting one-size-fits-all solutions that compromise on performance.

No Single Material Does Everything

The most important takeaway is that no single material excels at everything. Cotton’s softness and affordability make it perfect for casual wear but terrible for athletics. Merino wool’s versatility across temperature ranges and activities makes it worth the premium price for serious users but overkill for occasional casual wear. Synthetics deliver athletic performance at moderate prices but some people simply prefer the natural fiber feel. Understanding these trade-offs empowers better purchasing decisions.

For most people, owning socks in multiple materials makes sense. Athletic activities benefit from moisture-wicking synthetics or merino blends. Casual everyday wear works fine in cotton or bamboo blends. Cold-weather activities demand merino wool. Dress occasions call for smooth merino or quality synthetic dress blends. Building a varied sock collection with materials matched to uses delivers better overall performance than trying to find one perfect material for everything.

Quality Materials Pay Off Long Term

The investment in quality materials pays dividends through improved comfort, better performance, and often lower cost per wear despite higher upfront prices. Cheap cotton socks costing $4 but lasting four months actually cost more per wear than $20 merino socks lasting eighteen months while delivering superior comfort throughout their lifespan.

When shopping for socks, read material labels carefully and understand what blend ratios mean for performance. Marketing emphasizes premium materials like merino wool, but a sock containing only 30% merino won’t perform like 70% merino despite similar marketing. Know what you’re actually buying rather than being swayed by material name-dropping.

Consider the Complete Package

Remember that material is just one factor in sock selection. Proper sizing, quality construction, and appropriate design for your intended use all matter alongside material choice. The best material in poorly constructed socks still underperforms moderate materials in well-made socks. Consider the complete package rather than focusing exclusively on fiber content.

If you’re uncertain which material suits your needs, start with a single pair of the material you’re considering rather than immediately buying a dozen pairs. Test the material through your actual activities and washing routine. This methodical approach prevents expensive mistakes and helps you discover which materials work best for your specific feet and uses.

For comprehensive guidance on all aspects of sock selection beyond materials, explore our detailed guides on the complete sock sizing guide, best grip socks, best compression socks, best ankle socks, best crew socks, and non-slip socks to build a sock collection that serves all your needs perfectly.

The right material transforms your sock-wearing experience from constant foot awareness to comfortable invisibility. That’s when you know you’ve successfully matched materials to your needs.

Questions about choosing the right sock material for your specific needs? Share your activities and priorities in the comments (athletic use, casual wear, budget concerns, specific foot issues), and I’ll provide personalized material recommendations. The right material transforms your entire sock-wearing experience.