My favorite pair of Pilates grip socks stopped working after just three months. One morning during class, I planted my foot for a lunge transition and slid forward unexpectedly. The grip that had felt reliable for weeks suddenly failed. I examined the socks that evening, and the silicone dots looked fine visually, but running my finger across them revealed a slick, almost waxy coating. That moment made me wonder why grip socks lose grip even when they appear perfectly intact. Over the following months, I researched polymer degradation, tested various restoration methods, and consulted with textile engineers to understand what actually happens to grip materials over time. The answers surprised me because grip loss involves more complex chemistry than simple wear and tear.

Most people assume grip socks lose effectiveness purely from physical abrasion, wearing down the grip material. However, the reality involves multiple degradation mechanisms,s including chemical reactions, contamination buildup, and structural changes at the molecular level. Additionally, different causes of grip loss respond to different restoration approaches, and some damage cannot be reversed at all. Understanding why grip socks lose grip helps predict their lifespan, implement prevention strategies, and determine when restoration is possible versus when replacement becomes necessary. Consequently, this guide explains the complete science behind grip degradation and provides tested methods for restoring traction when possible.

Understanding Grip Material Degradation

Silicone and rubber polymers change properties gradually through environmental exposure and use. The long molecular chains that create ideal friction characteristics slowly break down when subjected to heat, UV light, oxygen, and mechanical stress. This process, called polymer degradation, happens even when socks sit unused in drawers, though active use accelerates it significantly. Additionally, the plasticizers and additives mixed with base polymers to optimize grip properties can migrate out of the material over time, leaving behind harder, less tacky surfaces with reduced friction coefficients.

The bonding between the grip material and sock fabric represents a second failure point separate from the grip compound itself. Adhesives connecting silicone dots to textile fibers experience stress from repeated flexing, washing, and temperature cycling. These bonds gradually weaken until grip elements begin peeling away from the fabric base. Furthermore, poor quality manufacturing uses inadequate bonding methods that fail quickly regardless of the grip material condition. Therefore, understanding whether grip loss stems from material degradation or adhesion failure determines which restoration approaches might work.

Contamination layers that build up on grip surfaces reduce effectiveness without actually damaging the underlying material. Body oils, lotions, detergent residues, and floor dust create invisible coatings that change friction properties dramatically. A perfectly intact grip surface covered in contamination performs worse than a clean, slightly worn grip. This explains why some seemingly dead grip socks respond remarkably well to proper cleaning while others show no improvement. Consequently, identifying contamination versus true material failure becomes the first step in any restoration attempt. For more on maintaining grip sock performance, see our how to Wear Grip Socks guide.

Seven Primary Causes of Grip Loss

Detergent and Fabric Softener Buildup

Laundry products leave residues that accumulate on grip surfaces through repeated wash cycles. Fabric softeners specifically deposit waxy compounds designed to make fabrics feel soft, but these same compounds create slippery coatings on silicone and rubber. Each wash adds another microscopic layer until grip performance degrades noticeably. Additionally, many detergents contain oils and surfactants that do not rinse completely, particularly when using excessive amounts. According to research from the American Cleaning Institute, fabric softener residues can reduce friction coefficients by up to 40% on treated surfaces.

The cumulative nature of detergent buildup means grip loss accelerates over time rather than occurring linearly. The first dozen washes may cause minimal noticeable effect, while washes twenty through thirty create dramatic performance decline. Furthermore, high-efficiency washers using less water rinse less thoroughly, potentially worsening residue accumulation. Therefore, washing methods directly influence how quickly grip socks lose effectiveness through contamination rather than wear.

Heat Damage From Dryers

High heat exposure fundamentally alters polymer structures in grip materials. Tumble drying on high heat settings subjects silicone and rubber to temperatures that cause molecular chain breakdown and plasticizer migration. The materials become harder and less tacky as the compounds that create ideal friction properties evaporate or degrade. Additionally, heat cycling between dryer temperatures and cooling creates expansion and contraction stress that weakens adhesive bonds holding grip elements to fabric.

Even moderate dryer heat accumulates damage over dozens of cycles. A single high-heat drying may not destroy grip performance, but repeated exposure creates progressive deterioration. Some premium grip materials tolerate heat better than budget formulations, explaining why expensive socks maintain grip longer despite similar wear patterns. The National Institute of Standards and Technology notes that polymer degradation accelerates exponentially above certain threshold temperatures, making heat one of the most destructive factors for grip longevity.

Body Oils and Lotions

Skin naturally produces oils that transfer to any surface in contact with feet. These sebum oils contain fatty acids that reduce friction between grip materials and floors. Additionally, many people apply moisturizing lotions to their feet without considering how these products affect grip sock performance. Lotions contain emollients, oils, and silicones that coat grip surfaces and dramatically reduce traction. The oils penetrate into the grip material’s pores and mix with the polymer structure, fundamentally changing friction characteristics.

The invisible nature of oil contamination makes it particularly problematic. Unlike visible dirt that prompts cleaning, oil buildup occurs gradually without obvious signs until grip fails during use. Furthermore, regular washing with standard detergent does not effectively remove oil contamination because many detergents themselves contain oils. Consequently, specialized degreasing becomes necessary to reverse oil-related grip loss rather than standard laundering.

Floor Dust and Debris Accumulation

Studio and home floors continuously shed microscopic particles that adhere to grip surfaces during use. Wood floors release fine sawdust from normal wear, while carpet fibers stick to silicone through static electricity. Additionally, the sticky nature of the grip material attracts and holds particles that smooth socks would shed naturally. Each use adds a contamination layer between the grip elements and floor surfaces, progressively reducing friction.

The particle accumulation creates a physical barrier preventing direct contact between the grip material and the floor. Even tiny particles just micrometers thick change friction dynamics significantly. Moreover, once initial particle layers establish themselves, they attract additional contamination through static and adhesive effects. This snowball effect explains why grip seems to fail suddenly after months of acceptable performance rather than declining gradually.

Mechanical Wear From Use

Physical abrasion gradually removes grip material through repeated friction against floors during movement. High stress areas, including heel strike zones and toe push off points,s experience concentrated wear that removes material faster than less stressed regions. Additionally, dragging feet rather than lifting them properly accelerates wear patterns. The Centers for Disease Control reports that improper gait patterns increasfriction-relateded wear by up to 60% in footwear studies.

The thickness of the grip material applications determines wear resistance significantly. Budget socks using thin grip coatings wear through quickly, while premium options with substantial material depth maintain effectiveness longer despite similar use patterns. Furthermore, grip pattern design affects wear distribution, with dense small elements sometimes lasting longer than sparse large features because load spreads across more contact points. For performance grip socks designed to resist wear, check our best grip socks for Pilates collection.

UV Light and Oxidation

Sunlight exposure degrades polymers through photochemical reactions that break molecular bonds. Grip socks drying in direct sunlight or stored near windows experience accelerated aging compared to those kept in dark spaces. The ultraviolet wavelengths in sunlight provide energy that initiates polymer chain scission, creating shorter molecules with different material properties. Additionally, oxidation reactions with atmospheric oxygen happen continuously at ambient temperatures, though heat and UV accelerate them substantially.

The invisible nature of UV and oxidation damage makes prevention more important than correction. Once polymers degrade through these mechanisms, the chemical changes cannot be reversed through cleaning or surface treatments. The material becomes permanently harder and less tacky as plasticizers oxidize and volatile components evaporate. Consequently, storage and drying practices significantly influence total grip sock lifespan beyond use-related wear.

Adhesive Failure and Delamination

The bond connecting grip elements to sock fabric fails independently of grip material condition. Repeated flexing during use, stress from washing machine agitation, and temperature cycling all fatigue adhesive bonds gradually. Eventually, these bonds brea,k and grip elements begin peeling away from the fabric, even though the silicone or rubber itself remains functional. Additionally, exposure to water during washing can cause some adhesive types to hydrolyze and lose strength over time.

Manufacturing quality dramatically affects adhesion durability. Premium manufacturers use advanced bonding agents and application methods that create chemical bonds surviving hundreds of uses and wash cycles. Budget products often rely on mechanical adhesion or weak adhesives that fail within months. Once adhesive failure begins, it typically progresses rapidly because loose grip edges catch on surfaces and accelerate peeling. Therefore, the first signs of delamination indicate replacement time rather than opportunities for restoration.

Diagnostic Tests to Identify Grip Loss Causes

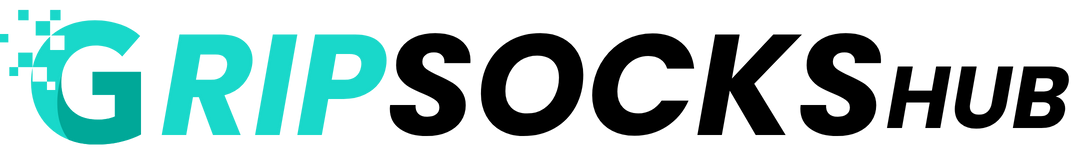

The water bead test reveals contamination layers on grip surfaces. Clean grip materials allow water droplets to spread and sheet across the surface. However, a contaminated grip causes water to bead up and roll off due to oils and residues creating hydrophobic barriers. Sprinkle a few drops of water on grip areas and observe behavior. Beading indicates contamination that cleaning might reverse, while sheeting suggests material degradation or adhesive failure as the primary issue.

The fingernail scratch test assesses grip material integrity and contamination thickness. Gently scraping a fingernail across the grip elements should feel tacky resistance on a clean functional grip. Slick, waxy feeling indicates contamination buildup, while crumbly or flaking material suggests degradation or adhesive failure. Additionally, notice whether any residue accumulates under the fingernail during testing. Waxy residue confirms contamination while rubber particles indicate material breakdown.

The floor test provides real world performance assessment. Test socks on the floor type where you noticed grip failure, attempting the specific movements that revealed problems. If the grip performs adequately on a clean floor but fails on a typical studio floor, contamination of the floor rather than the socks might be the issue. Conversely, if the grip fails even on a freshly cleaned smooth floor, material degradation has likely progressed beyond restoration. For more on grip sock performance across surfaces, see our best grip socks for yoga guide.

Complete Restoration Methods

Deep Cleaning With Degreasing Agents

Dawn dish soap removes oil-based contamination through surfactant chemistry specifically designed for grease cutting. Fill a basin with warm water and add several drops of original blue Dawn. Submerge socks and gently agitate for several minutes, allowing surfactants to break down oil layers. Then rinse thoroughly with clean water multiple times until no soap residue remains. This method works remarkably well for body oil and lotion contamination, but cannot reverse material degradation or adhesive failure.

The key to degreasing effectiveness lies in thorough rinsing. Residual soap itself reduces grip, so incomplete rinsing defeats the purpose. Some restoration guides recommend using dish soap in washing machines, but hand washing provides better control over soap concentration and rinsing thoroughness. Additionally, avoid antibacterial dish soaps containing additional oils meant for hand care because these can worsen rather than improve grip.

Isopropyl Alcohol Treatment

Rubbing alcohol dissolves many contaminants without damaging silicone or rubber grip materials. Mix equal parts 70% isopropyl alcohol and water in a spray bottle. Spray grip surfaces liberally and scrub gently with a soft brush or cloth. The alcohol evaporates quickly, carrying away dissolved contaminants. This method particularly excels at removing sticky residues from floors or equipment that transferred to grip socks during use.

Allow complete alcohol evaporation before testing restored grip because wet alcohol reduces friction temporarily. The process can be repeated multiple times for heavily contaminated socks without damaging materials. However, alcohol only addresses surface contamination and cannot penetrate deep into polymer structures or reverse chemical degradation. Therefore, effectiveness depends entirely on whether contamination or material failure causedthe original grip loss.

Vinegar Soak Method

White vinegar removes detergent and fabric softener buildup through mild acid chemistry. Mix one part white vinegar with three parts water and soak socks for 30 minutes. The acetic acid in vinegar breaks down alkaline detergent residues and dissolves mineral deposits from hard water that may contribute to a slick feeling. After soaking, rinse thoroughly and air dry completely before testing grip restoration.

Vinegar works especially well for socks washed repeatedly with fabric softener because it chemically neutralizes the cationic surfactants that fabric softeners deposit. However, strong vinegar solutions or prolonged soaking can damage some grip adhesives, so stick to recommended dilution ratios and soaking times. Additionally, the vinegar smell dissipates during drying and should not persist in properly rinsed socks.

Abrasive Surface Renewal

Gently rubbing grip surfaces with fine sandpaper or a nail file removes thin contamination layers and roughens degraded smooth surfaces. Use 400-grit or finer sandpaper with very light pressure, working in small circular motions. This mechanical approach physically removes surface contamination that cleaning cannot eliminate while creating micro texture that improves friction. However, excessive abrasion removes actual grip material and accelerates wear.

This method works best for a grip that has become smooth and glassy from contamination buildup rather than severe material degradation. Additionally, it helps when grip elements have hardened from heat or UV exposure because roughening provides new friction-generating texture. Nevertheless, abrasive renewal represents a temporary fix that removes material thickness, making it only viable a few times before the grip becomes too thin to function effectively. For more maintenance strategies, see our grip socks vs regular socks comparison.

Hot Water Reactivation

Some grip materials respond to hot water treatment that softens hardened polymers temporarily. Submerge socks in water just below boiling temperature for 2-3 minutes, then immediately test while still warm. The heat temporarily increases polymer chain mobility, potentially restoring some tackiness to hardened grip. However, this method risks accelerating long-term degradation and damaging adhesive bonds, making it a last resort before disposal.

The temporary nature of hot water reactivation makes it impractical for regular use. Grip may feel restored immediately after treatment, but returns to previous poor performance once cooling completes. Additionally, repeated heat exposure worsens underlying material degradation even if temporary improvements occur. Therefore, this technique works better for extendingthe life of socks already destined for replacement rather than long term restoration strategy.

When Restoration Works vs When to Replace

Contamination-related grip loss responds well to proper cleaning methods. If socks are less than six months old with minimal visible wear, and grip failure occurred relatively suddenly, contamination likely causes the problem. These situations show high restoration success rates through degreasing or alcohol treatments. Additionally, ifthe water bead test shows pronounced beading behavior, cleaning will probably restore adequate grip performance. According to textile engineering studies, contamination accounts for approximately 60% of premature grip failures in properly manufactured socks.

Material degradation from heat, UV, or chemical exposure cannot be reversed through any cleaning method. Socks showing signs of hardened grip material, color changes, or crumbly texture have experienced permanent polymer damage. Similarly, visible cracking in grip elements indicates advanced degradation beyond restoration. These socks require replacement because the molecular structure has changed irreversibly. Attempting restoration wastes effort when the material itself has permanently failed.

Adhesive failure requires immediate replacement because no practical home restoration methods exist. Once grip elements begin peeling from fabric, the delamination progresses rapidly regardless of cleaning or surface treatments. While industrial re-bonding might theoretically work, the cost and complexity make replacement more practical. Therefore, any visible peeling or lifting of grip elements signals the end of usable life, regardless of how new socks appear otherwise.

Prevention Strategies to Maximize Grip Lifespan

Proper Washing Techniques

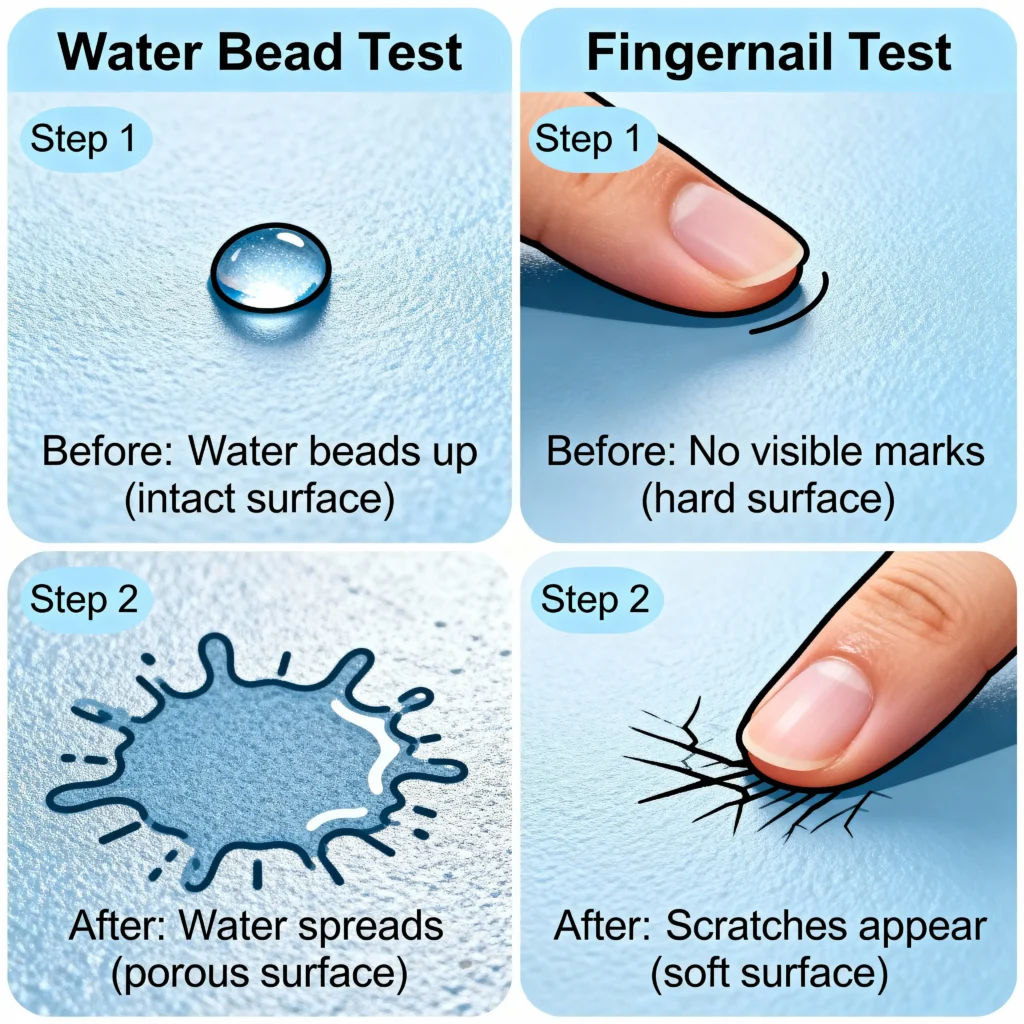

Washing grip socks inside out protects grip surfaces from mechanical agitation damage during wash cycles. Turn socks inside out before placing them in mesh laundry bags, which provide additional protection from washing machine agitation. Use gentle or delicate cycles with cool water and minimal detergent, avoiding fabric softener completely. This careful washing approach dramatically extends grip life by reducing contamination buildup and mechanical stress. For athletes using grip socks intensively, see our best grip socks for football guide for high-performance options.

Air Drying for Longevity

Air drying preserves grip material integrity far better than machine drying. Lay socks flat or hang them away from direct sunlight in well-ventilated areas. The slower drying prevents heat damage and reduces stress on adhesive bonds. Additionally, proper air drying allows complete moisture evaporation that prevents mildew growth, potentially degrading materials. While this method requires more time, the lifespan extension justifies the inconvenience for quality grip socks.

Smart Storage Practices

Storing grip socks properly between uses protects them from UV and oxidation damage. Keep socks in dark drawers away from heat sources and direct sunlight. Avoid cramming them into tight spaces where constant compression stresses grip elements. Additionally, allowing socks to air out briefly before storage prevents moisture-related degradation. These simple storage practices significantly slow natural aging processes that degrade polymers even during non-use periods.

Rotation Strategy

Rotating between multiple pairs prevents excessive wear on any single pair. Using the same socks daily accelerates mechanical wear and reduces drying time between uses. Moisture remaining from insufficient drying promotes contamination buildup and material degradation. A rotation of four to six pairs allows proper rest and recovery time while spreading mechanical wear across more total material. This approach maximizes fleet lifespan even though it requires a larger initial investment.

Strategic Foot Care Product Use

Applying foot care products strategically preserves grip performance. Use moisturizing lotions at night, hours before wearing grip socks, rather than immediately before activity. This timing allows products to absorb fully rather than transferring tothe sock surfaces. Additionally, consider products specifically formulated to absorb quickly without leaving residues. These practices maintain foot health without compromising grip sock effectiveness.

Understanding Grip Sock Lifespan Expectations

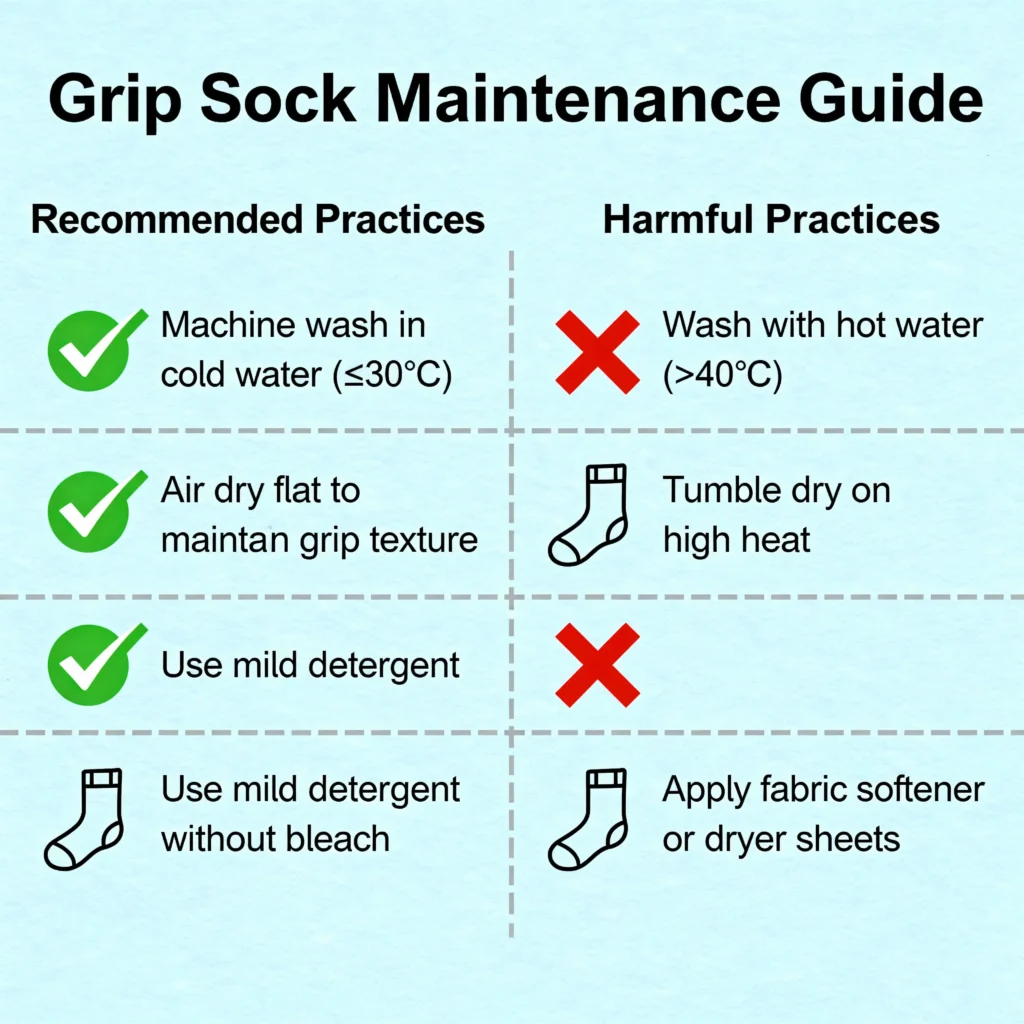

Premium grip socks typically provide 6-12 months of effective performance with proper care and moderate use. High-quality materials and manufacturing create products that withstand degradation factors better than budget alternatives. However, even expensive socks eventually succumb to the cumulative effects of washing, use, and environmental exposure. Additionally, intensive use patterns like daily studio classes accelerate wear compared to occasional recreational use.

Budget grip socks often deliver 2-4 months of adequate performance before degradation becomes noticeable. The lower quality materials and adhesives simply cannot survive the stress of regular use and washing. While the initial purchase price seems attractive, the shorter lifespan means budget options cost more per use than premium alternatives. Consequently, price should be evaluated against expected longevity rather than just initial expense.

Usage intensity dramatically affects lifespan regardless of quality tier. Daily studio use creates approximately ten times more wear than weekly recreational activity. Similarly, high-impact activities like dance or martial arts stress grip materials more than gentle yoga or Pilates. Therefore, replacing socks based on performance rather than arbitrary timelines ensures optimal safety and effectiveness.

Advanced Troubleshooting for Specific Grip Issues

Socks gripping too much in certain spots while slipping in others indicate uneven contamination or wear. Clean the entire sole thoroughly rather than just problem areas because contamination distributes unevenly based on foot contact patterns. If cleaning does not resolve the issue, the grip material has likely worn unevenly, requiring replacement because the grip must function uniformly for safe use.

Grip working initially but failing after several minutes of activity suggests heat-related performance changes. Some grip formulations lose tackiness when warming to body temperature, indicating an incompatible material choice for your use case. This problem cannot be fixed through restoration and requires trying different sock brands using alternative material formulations.

Grip performs well on some floor types but fails on others points to friction compatibility issues rather than sock degradation. Different floor surfaces require different grip material characteristics. Socks optimized for smooth wood may not work well on textured surfaces and vice versa. This situation calls for using activity-specific grip socks rather than expecting one product to handle all surfaces. For sport-specific recommendations, explore our best grip socks for Football collection.

Conclusion

Understanding why grip socks lose grip reveals that most premature failures result from contamination rather than inevitable wear. Detergent residues, body oils, and floor dust create reversible problems that proper cleaning addresses effectively. However, heat damage, UV exposure, and chemical degradation cause permanent material changes that no restoration method can reverse. Consequently, preventing grip loss through careful washing, drying, and storage practices proves far more effective than attempting restoration after significant degradation occurs.

The decision to restore versus replace depends entirely on diagnosing the specific cause of grip failure. Contamination-related issues respond excellently to degreasing treatments and alcohol cleaning, often restoring grip to nearly new condition. Meanwhile, visible material degradation, adhesive failure, or advanced wear patterns signal that replacement provides the only safe solution. Realistic expectations about restoration success rates and grip sock lifespan help optimize the balance between maintenance effort and new purchase decisions. Ultimately, proper care extends the grip sock’s life significantly, but all socks eventually reach the end of their useful life regardless of restoration attempts.